- February 13, 2025

Hydrographics Film & Water Transfer Printing: The Art of Water Dip Painting

If you want to give objects an unconventional and personalized touch, hydrographic film water transfer printing, also called water dip painting, is your best bet. This revolutionary coating technique permits highly detailed designs and patterns to be placed on various items with great care and toughness. Hydro dipping is a revolutionary step in custom design that doesn’t require hand painting but still delivers an astonishing finish, from a car part to a helmet, gun, or household item.

What is Hydrographic Film Water Transfer Printing?

Hydrographics or water transfer printing is a method in which an object gets dipped into a vat of water where a film with printed patterns is placed. Hydrographic film water transfer printing uses specially designed films with particular designs. This film is submerged in water to create a vat. As the object is immersed into the vat, the motifs on the film dissolve and are adhered firmly onto the object’s surface, providing an attractive and perfect finish to the item.

This method is popular in car customization, sports gear, home furnishings, and some industrial uses. Hydro dip painting allows the simulation of different materials like wood, carbon fiber, complex camouflaged prints, and even detailed abstract designs, which are complicated to achieve with standard painting.

How Does the Hydro Dipping Process Work?

The process of water transfer printing is straightforward and involves a few key steps:

- Surface Preparation – The object to be dipped is thoroughly cleaned and primed to ensure the paint adheres properly.

- Base Coating – A base coat of paint is applied, acting as the design’s background color.

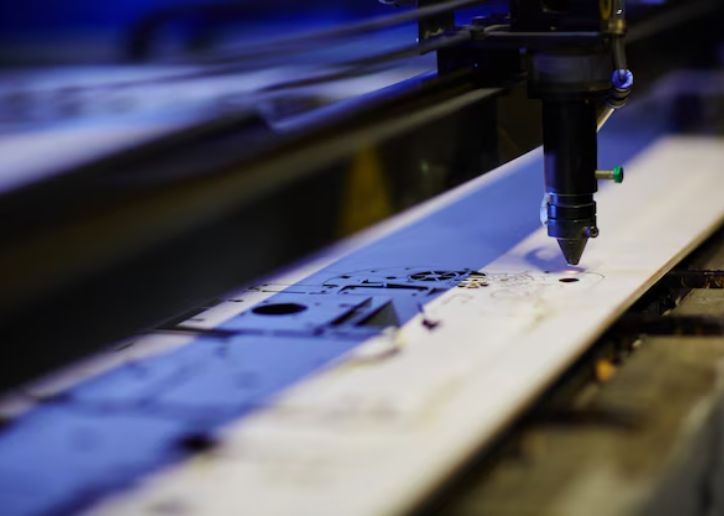

- Film Placement – A printed hydrographic film is placed on the water’s surface in a dipping tank.

- Activation – A chemical activator is sprayed over the film, dissolving the film’s backing and leaving the ink pattern floating.

- Dipping – The object is slowly dipped through the floating ink, wrapping the design around its surface.

- Rinsing & Drying – Any excess film residue is washed off, and the item is dried thoroughly.

- Clear Coating – A protective clear coat is applied to ensure durability and resistance to wear and tear.

Benefits of Hydro Dipping

- Custom Designs – Choose from thousands of patterns or create your unique design.

- Durability – The final finish is strong, resistant to fading, and long-lasting.

- Versatile Application – Works on plastic, metal, wood, glass, and ceramics.

- Cost-Effective – Achieve a high-end look without the expense of airbrushing or custom paint jobs.

- 360-degree Coverage – Unlike traditional painting, Hydrographics can fully wrap around complex shapes.

What Can You Hydro Dip?

Almost any non-porous object can be water dip painted, including:

- Automotive parts (dashboards, rims, grilles)

- Motorcycle and bicycle frames

- Helmets and sports gear

- Firearms and hunting equipment

- Home décor items (vases, furniture, picture frames)

- Gaming consoles and controllers

Why Choose Hydro Dip Over Traditional Painting?

Hydro dipping stands out because it eliminates brush strokes, offers seamless designs, and allows for customization that traditional painting cannot achieve. Unlike stickers or decals that can peel over time, hydrographics create a permanent bond with the surface, ensuring long-lasting quality.

How to Maintain Hydro-Dipped Items

To keep your hydro-dipped products looking fresh:

- Avoid harsh chemicals when cleaning.

- Use a microfiber cloth to prevent scratches.

- Apply wax or a ceramic coating for added protection.

- Store items away from direct sunlight to prevent UV damage.

Get Started with Hydrographics Today!

Personalizing your items with hydrographic film water transfer printing has never been it’ser. Whether you’re a DIY or seeking professional services, water dip painting is a game-changer in customization. Bring your ideas to life with stunning finishes that turn ordinary objects into extraordinary pieces!

Best Digital Marketing Consultant. I have more than 5 years of experience in SEO, SMO, PPC and Internet Marketing.